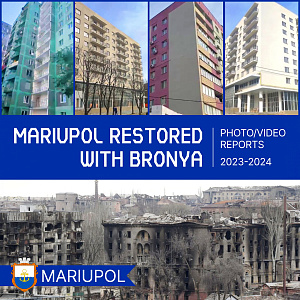

Thermal insulation Bronya Facade

Extra-fine thermal insulation Bronya Facade. This is the first in the world extra-fine ceramic thermal insulating material which can be applied by 1mm layer at a time and which has vapor permeability of a high-quality facade paint. Extra-fine thermal insulation Bronya Facade has been developed especially for concrete surfaces. Due to high heat-reflective properties and reduced labor costs for coat application if compared to similar extra-fine thermal insulators at least by half, it will be the best solution for construction professional thermal insulation for you and your clients.

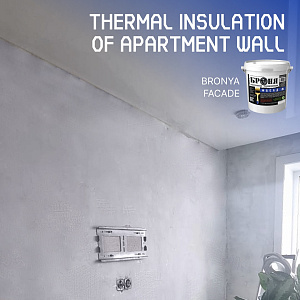

Extra-fine thermal insulation Bronya Facade is an extra-fine liquid ceramic thermal insulating material which can be applied by 1 to 3mm layers at a time (which depends on application type) and which has vapor permeability of a high-quality facade paint (0.03). Bronya Facade is a weather-resistant high-viscous compound specially developed for thermal insulation of vertical surfaces. The coat applied inside and outside of a wall forms single jointless surface and preserves heat all over the room what has a positive effect on microclimate.

Bronya Facade reflects up to 80% of visible solar and infra-red radiation spectrum. It results in significantly reduced indoor heating in summer time and lower conditioning expenditures, and in winter time it can reduce heat loss by up to 30%. Thermal insulation Bronya Facade is a long-life material having high adhesion to any construction materials and repellent properties along with good vapor permeability.

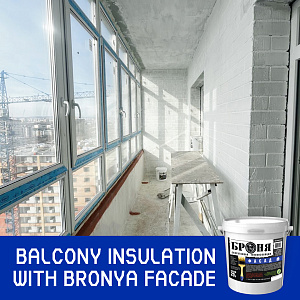

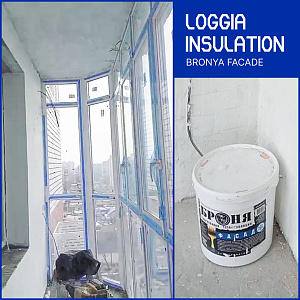

Liquid ceramic thermal insulation Bronya Facade is used for heat insulation of plastered, concrete, brick, wooden and other surfaces of enclosing structures of buildings and constructions when for inside and outside jobs. Ceramic thermal insulation Bronya Facade can be covered with emulsion-based acrylic paint or papered. Bronya Facade can be tinted only provided that it follows our process sheet and our recommendations on colour paste selection and technical details.

Application of Bronya Facade helps to:

- ensure thermal insulation both inside and outside a wall;

- preserve usable area size (with indoor thermo insulation);

- not increase structural unit load;

- insulate facades of complicated architectural solutions (including reconstruction works);

- improve premises thermal comfort;

- reduce expenditures and time for construction works.

Thermal insulating paint Bronya Facade is also great if applying together with Bronya Antorust modification. For instance, rated thickness of an extra-fine thermal insulation to be applied onto a ferrous metal tank is 2.5mm of mascoat, alfatek, tsm ceramic, teplos-top and etc, as well as our basic modification Bronya Classic. At least 6 layers were required (1st layer of primer plus 5 layers of 0.5mm coat with interlayer drying during 24 hours. Our solution - just three layers (!):

1st layer 0.5mm of Bronya Antirust (this is not only rust lock but also modifier, adhesive agent and hydrobonder (due to its high indicator of film formation)

2nd layer applied after 24 hours 1mm of Bronya Facade

3rd layer applied after 24 hours 1mm of Bronya Facade

Order a free sample and you will see that claimed specifications are true!

You can find Bronya Facade guideline in Technical Documentation section.

Extra-fine thermal insulation Bronya Facade is delivered in the following packages:

| Bronya Facade 5L | Bronya Facade 10L | Bronya Facade 20L |

|

|

|

Extra-fine thermal insulation Bronya Facade NF

Bronya Facade NF is identical by form and package with low-flammable (basic) modification.

Video test for Bronya Facade NF not-flammability

It is important to note! as of today, we are not aware of similar not flammable thermal insulating coats having identical with our basic modifications thermal conductivity of 0.001; - and also we are not aware of complete competing equivalents of these modifications produced by other LCTIM manufacturers.

However the market has:

- non-flammable coats with NF (non-flammability) certificate including coats produced by manufacturers of LCITM with some (or with no) thermophysical effect who suggest to apply it onto their basic modification (which thermal conductivity is not confirmed by the way) in order to supposedly receive finishing thermal insulating coat with non-flammability certification... No comments

- liquid ceramic thermal insulating material having non-flammability certificate but which claimed thermophysics is 2-8 times higher than 0.001 (in most cases with no legal confirmation of thermal conductivity at all).

Table of specifications for Bronya Facade

| Indicator | Unit | Value |

|---|---|---|

| Coat form | Smooth, uniform, mat white color film | |

|

Coat resistance to temperature

drop from -40°С to +60° С

|

Coat form | no changes |

|

Service life for concrete and metal surfaces in boreal climate (Moscow)

|

years | not less than 15 |

|

Material thermal conductivity coefficient |

W/m° С | 0,0012 |

|

Material vapor conductivity coefficient |

mg/m h Pa | 0,03 |

| Surface temperature during material application | °С | from +7 to +120 |

|

Service temperature |

°С |

from -60 to +120 |

| Material density at 20°С, kg/m3 | kg/m3 | 600±10% |

| Volatile matter content, max | % | 43 |

| Hydrogen ion exponent | рН | 7,5-11,0 |

| Drying and film formation time at 20±2° С, min | h | 24 |

Coat adhesion with respect to peeling-off force, min

|

MPa |

1,3 2,2 |

Coat resistance to static impact at 20±2° С, min

|

Coat form |

no changes no changes |