Thermal insulating coat Bronya Light Nord

Applied at temperatures from -30°С up to +30°С

Background of the thermal insulating coat Bronya Light Nord.

Market today offers a wide variety of materials which help solving thermal insulation tasks. One of these is aerogel or so called "nanogel". It is a thermal insulating component with a very low heat conductivity index which tends towards zero due to considerably decreased convection.

- Main aerogel properties:

- Light weight;

- Resistance to temperature differences;

- High-temperature stability;

- High strength;

- Very low heat conductivity.

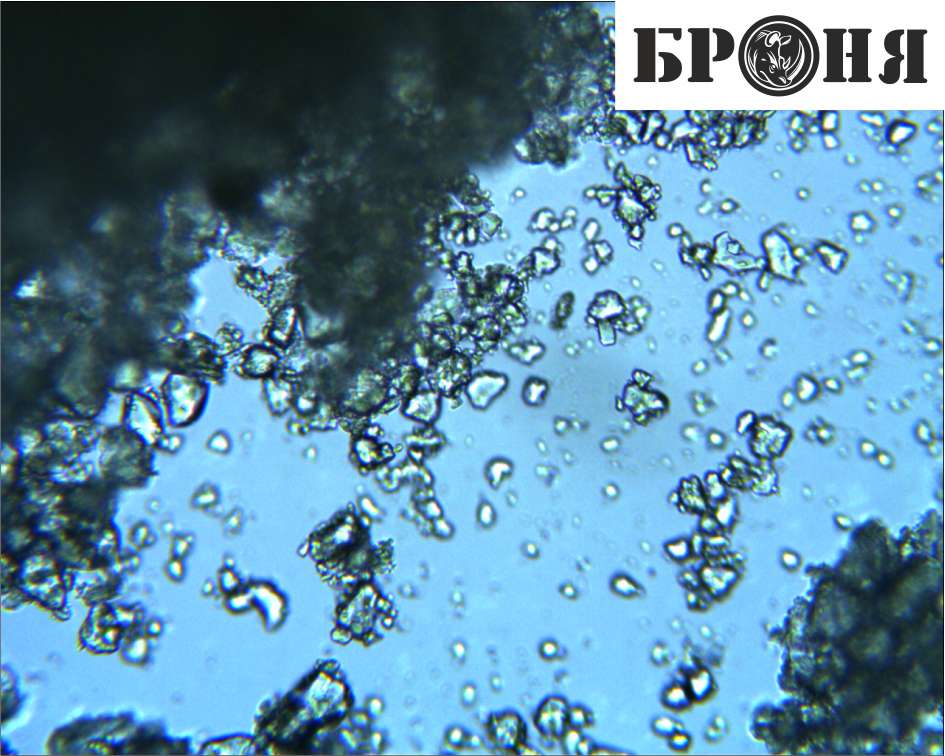

Nanogel powder is a base of the modification thermophyisical properties in the thermal insulating coat Bronya Light Nord line - through an electronic microscope.

This is perhaps the best material for thermal insulation purposes: light, quite fast, rust- and mold-resistant, non-flammable and certainly unsinkable. Aerogel can drastically decrease heat loss during use of buildings and structures or, on the contrary, cut-down costs for air conditioning and freezing plants operation.

This is quite a challenge to develop a thermal insulating material which, preserving aerogel's set of positive properties, would be convenient and user-friendly for real application and would meet all regulatory requirements imposed for thermal insulating materials. Thats why aerogel been unpopular until recently.

It is also interesting that aerogel was not almost used for the intended purpose. Until recently, thermal insulating materials created on the aerogel basis had been so expensive that such materials as polyurethane foam, mineral wool and other materials could not merely compete. They were also quite bulky and unhandy for use.

Chemical industry's progress has been huge during last decades and it made production of aerogel available especially when this nanogel is produced as a powder. As a result, producers of construction materials could now afford usage of aerogel as a component in the form of so called "nanogel powder".

Singularity of the thermal insulating coat Bronya Light Nord is in inheriting all positive nanogel properties and at the same time extending and supplementing its application scope and functional capabilities.

Bronya Light Nord outstanding features.

An outstanding feature of the Bronya Light Nord modification differentiating it from other Bronya modifications is the following:

- Thermophysical properties of 2-3mm of Bronya Light Nord are identical to those of 100-150mm of brickworks.

- Usage of thermal insulating filling compound is cost-efficient (for solving additional winterization issues) compared to almost any insulation as the cost of thermal insulating coat Bronya Light Nord is comparable to regular plasters.

- It can be used with surfaces which require light insulation (to eliminate cold wall effect, frost penetration and formation of condensate during severe frost) and also where thermophysical properties would require less than 1mm of LCTI Bronya (Facade or Classic).

- It can be used for multi-layer enclosing structures with a capability to apply any construction material over our warm filling compound;

- Filling and thermal insulating works can be performed simultaneously cutting down labor costs significantly.

- The material can be applied using plaster sprayers and airless spraying apparatus at pressure not higher 90bar.

- Layer thickness can be up to 3mm at one run;

- The material will dry faster if the temperature raises to 50-60°С;

- The material can be agitated by a construction mixer at any revolutions;

What could not be made before, now is possible with Bronya Light Nord!

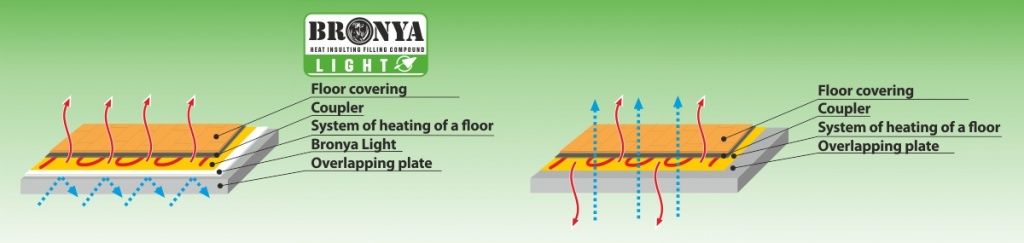

1. Floor insulation using "warm floor" system.

Standard installation methods of underfloor heating require an insulator between a floor slab and system heating elements what considerably increases threshold thickness. Now you don't have to use standard insulators which in the course of time lose their strength and shrink. Bronya Light Nord can ensure thermal insulation better than any other material and significantly lessen warm floor thickness.

Bronya Light Nord creates a thermal barrier preventing from frost penetration from outside and reflecting heat coming from the heating system.

Warm floor. Heat exchange process with insulation and without it.

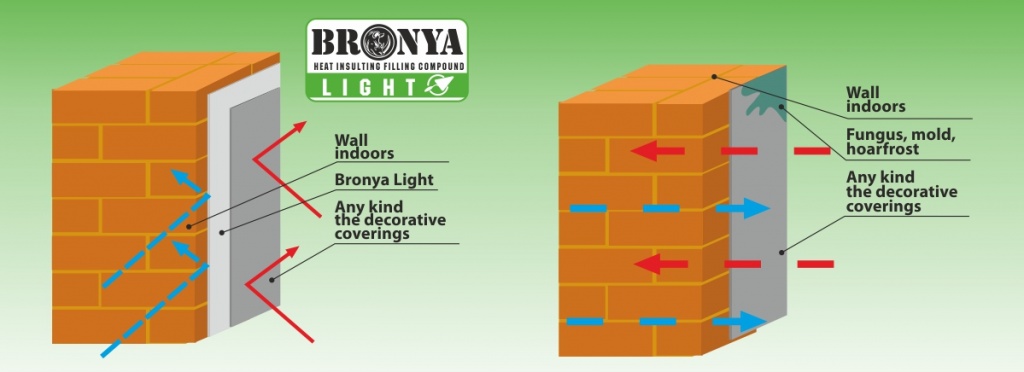

2. Building walls will be insulated and plastered in one run if using Bronya Light Nord.

Building wall insulation is quite a complicated and labour-consuming process which cannot be always performed using conventional construction materials which are bulky and require additional labour costs for installation. Thermal insulating coat Bronya Light Nord can be coated with any decorative materials such as wall papers, paints, decorative plasters, tile adhesive and etc.

Building walls. Heat exchange process with insulation and without it.

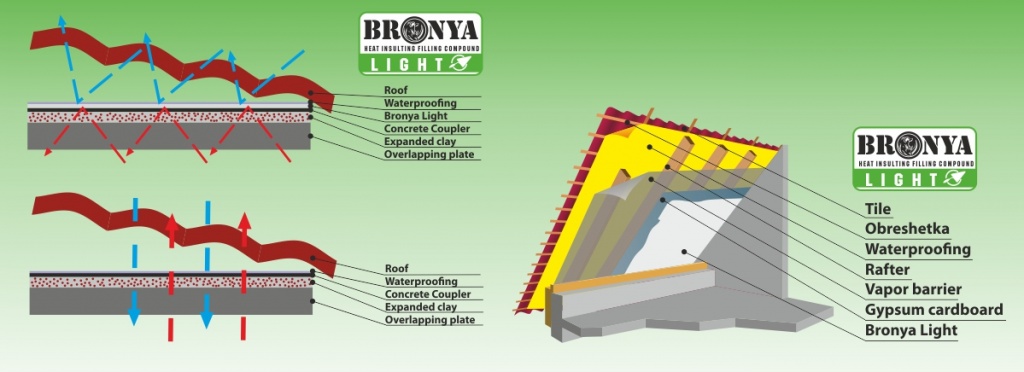

3. Roof insulation.

Bronya Light Nord enables for roof insulation using materials which do not make structures heavier and at the same time create thermal barrier from outside ambient. Therefore, there is no heat loss, internal icing, condensate and icicles formation in the cold period and warming-up in the warm period is considerably lower.

Roof. Heat exchange process with insulation and without it.

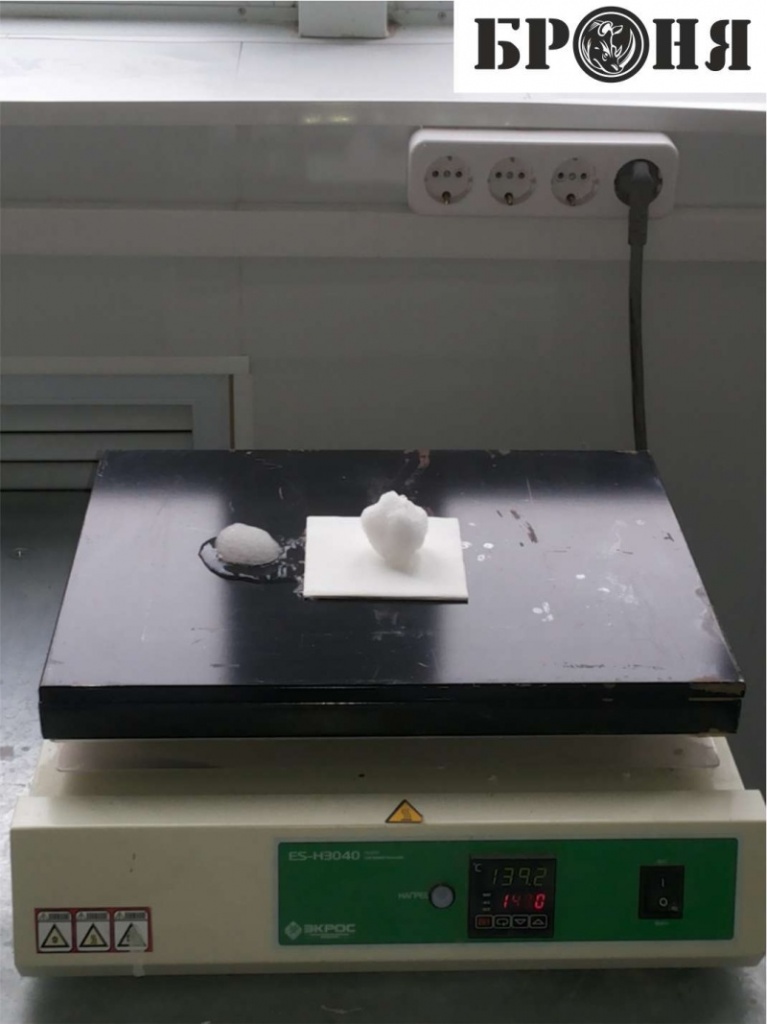

Explicit experiments demonstrating high quality of the thermal insulating coat Bronya Light Nord:

1. Apply 3 mm of the thermal insulating filling compound onto an electrical heat plate and after complete drying turn it on. Place an ice cube and your hand onto the isolated and not isolated surface and you will see the difference.

Pic.1. Heat plate, Bronya Light Nord has been |

|

Pic.2. Plate temperature is +140º С. |

|

Pic.3. Experiment with ice cubes. |

|

|

|

|

2. You can also perform a simple experiment - apply just 1mm of the thermal insulating coat Bronya Light Nord onto for instance a brick from one side and after it's dried, take it into your hands from the both sides (coated and not coated) and you will notice the difference (the coated side pulls heat from your hand not as much as the other side). Same happens with a wall in a building.

Pic.1. Face brick |

Pic.2. Brick coated by Bronya Light Nord |

3. Gypsum plasterboard is coated by the thermal insulating coat Bronya Light Nord; half of the plasterboard remains uncoated for a more visible effect. The plaster board is placed into a freezer with coated side down, then the freezer is cooled down and measurements are taken. This experiment allows to reproduce actual operating conditions of buildings' enclosing structures. Temperature in the freezer goes down to -18ºС and then readings are taken from isolated and not isolated surface.

| Measurement | Value, ºС |

|---|---|

|

Temperature in the freezer |

-18 |

|

Ambient air temperature |

25,6 |

|

Temperature of the isolated area surface |

19,2 |

|

Temperature of the not isolated area surface |

7,4 |

According to the experiment data:

Pic.1. Freezer |

Pic.2. Temperature inside freezer is -18ºС |

Pic.3. Temperature of plasterboard isolated area is +19ºС |

|

More details about Bronya Light Nord modification.

In comparison to all known conventional filling material, a distinctive feature of the thermal insulating coat Bronya Light Nord is that apart from its primary job, which is leveling of the base surface, Bronya Light Nord serves as a heat- and sound-isolating coat and also prevents from condensate and mold formation.

It should be also noted that the thermal insulating coat Bronya Light Nord has such high thermal insulating properties that heat permeability coefficient of the Bronya Light Nord coat when tested in accordance with GOST 7976-99 is lower than any conventional insulator.

Thermal insulating coat Bronya Light Nord is non toxic, does not contain harmful volatile compounds and is absolutely safe for people suffering from allergy what is confirmed by Sanitary Epidemiological Expertise issued by Healthcare Federal State-funded Institution "Hygiene and Epidemiology Center in the city of Moscow". Flammability class of the thermal insulating coat Bronya Light Nord is F1 (low flammable), fire growth rate in case of fire equals zero (Certificate of Conformity NoПС000277). Also we have absolutely non-flammable modification Bronya Light Nord NF. Thus, application of the thermal insulating coat Bronya Light Nord ensures comfort living conditions. This is the reason why most design and estimate companies include this material into multiple storage buildings design.

Thermal insulating coat Bronya Light Nord has been issued a Certificate of Class Approval. Russian Maritime Registry of Shipping confirms high quality of the Bronya extra-fine thermal insulation.

Special composition of the thermal insulating coat Bronya Light Nord enables for simultaneous plastering and heat insulating works on building and structure facades, cutting down labor costs and reducing time for performing the work. Thermal insulating coat Bronya Light Nord has high adhesion, weather resistance and service life durability indicators.

Application of the thermal insulating coat Bronya Light Nord in production facilities allows for increased power efficiency of an enterprise, reduced heating and cooling costs what helps to cut down production expenditures and to improve working conditions. It can be used for marine equipment.

Bronya Light Nord in constructional thermal insulation

|

Bronya Light Nord scope of application |

Advantages and effectiveness |

|---|---|

| Thermal insulation of facades buildings during construction, reconstruction and restoration |

- Significant reduction of heat loss; - Elimination of thermal bypass; - Possibility to perform plastering and thermal insulating works simultaneously; - Protection of enclosing structures from hostile conditions and structural damage; - Protection of enclosing structures from temperature drops; - Reduction of capital and operational expenses during facade - repair works, increase of time between repairs. |

| Thermal insulation of internal surfaces of living quarters and production facilities' enclosing structures |

- Significant reduction of heat loss; - Elimination of wall freezing; - Prevention from condensate and mold formation; - Preservation of room useful area; - Possibility to apply any decorative coat over the warm filling compound; - Reduction of labor costs and time to perform works in comparison with other methods. |

| Thermal insulation of building roofs, metal shed and garage roofs, mansard floors. |

- Significant reduction of heat loss; - Prevention from inside warmup; - Reduction of air conditioning costs; - Prevention from frost penetration and condensate formation inside a roof; - No additional structural load; - Elimination of icicle formation; - Reduction of labor costs and working time; |

| Thermal insulation of window and door reveals, recessed and standard balconies, projecting parts of steel and concrete structures, monolithic slab ends; |

- Significant reduction of heat loss; - Elimination of thermal bypass; - Prevention from condensate formation; - Reduced labor costs and working time in comparison with other methods. |

|

- Possibility to perform works in facilities which have been already put into operation; - Elimination of thermal bypass; |

You can download Bronya Light Nord Guidelines in Section Technical Documentation.

Thermal insulating coat Bronya Light Nord is delivered in plastic 20 liter buckets.

|

Bronya Light Nord 20L |

|

|

|