Fire retarding properties comply with GOST P 53295-2009.

Fire retarding paint or Bronya Fire Protection (R45, R60, R90, R120) is used to improve fire safety of enclosing structures. Application procedure for the protection material is simple, making any additional installation works unnecessary. Fire protective paints are reliable and durable and therefore fire protection using paint is convenient and reasonable. This is most true for hard-to-reach places because you don't have to disassemble structures to perform repeated fire suppression works.

Dependence of BRONYA FIRE PROTECTION coat thickness (mm) on the required fire resistance rating (R) and mass factor (MF)

|

Mass factor, mm

|

Fire resistance rating, min |

|||||||

|

45 |

60 |

90 |

120 |

|||||

|

thickness, mm |

consumption, kg/m² |

thickness, mm | consumption, kg/m² | thickness, mm | consumption, kg/m² | thickness, mm | consumption, kg/m² | |

| 2,4 | 1,2 | 1,69 | 1,53 | 2,155 | - | - | - | - |

| 3,4 | 1,07 | 1,59 | 1,38 | 2,03 | 2,0 | 2,82 | - | - |

| 5,8 | 0,62 | 0,87 | 0,81 | 1,142 | 1,76 | 2,61 | - | - |

| 7,2 and more | 0,65 | 0,95 | 0,85 | 1,25 | 1,3 | 1,83 | 2,3 |

3,2 |

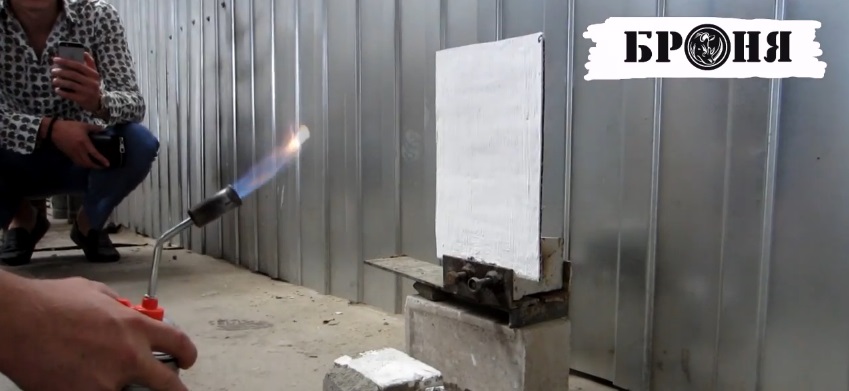

Experiment with the fire retarding compound BRONYA FIRE PROTECTION

Advantages of the Bronya fire retarding composition

- Good market price;

- Low consumption with very high fire protective and physical and mechanical characteristics;

- When used together with LCTIM, the coat does not impair its thermo-physical properties (including those of competing brands) and allows the system to get the non-flammable rating;

- Unlike its equivalents, Bronya Fire Protection should be colored, but this does not impair fire resistance of the surface;

- Profitable option for fire protection tasks;

- Rational labor costs and low cost of production of works.

- The coat (without additional protection layer) is designed for application inside buildings for 30 years.

Quality of Bronya Fire Protection composition enables what before has been considered impossible in Russia: to protect light steel structures reaching R120 rating. The composition has been specifically developed for use in sports and infrastructure facilities where structural load is low with a large area of constructions and bearing steel mass factors are small. With all this, traditional advantages of the Bronya Fire Protection coat are entirely preserved which are low cost, easy application and long service life.

Fire protection tasks for each facility are different. Our specialists help to choose the best option for each purpose. Recommendations on protection system choice, development of technical specifications, expert approvals, calculations. Engineering team will advise on design issues concerning fire safety as well as preparation for performing the works. In some cases our consultations lead to significant reduction of fire protection costs.

Bronya Fire Protection working principle

When the coat is heated, fumes and inert gases which slow down and do not sustain combustion are exhaled to replace oxygen thus ensuring fire protection. Therefore, fire retarding paints not only block thermal convection but also considerably mitigate and suppress flame. At the same time, the upper layer thickens, cokes up and stiffens. The paints contain fire retarding agents, special gas-forming agents, foaming layer stabilizers and heat-resistant elements based on the polymer binder.

Fire retarding compound Bronya Fire Protection - before exposure to fire

Fire retarding compound Bronya Fire Protection - before exposure to fire  Fire retarding compound Bronya Fire Protection - after exposure to fire

Fire retarding compound Bronya Fire Protection - after exposure to fire

Scope of application

- Steel structures in oil refinery plant infrastructure

- Chemical production facilities including those which are a source of weak and medium acid or alkaline environment

- Open and closed parking areas, stands, fly-over bridges

- Civil engineering facilities without any restrictions

- Other facilities where application of fire retarding paints without finishing coats is a better option.

Technical specifications of the fire retarding compound Bronya Fire Protection

| № | Indicator | Normal value for this grade |

|---|---|---|

| 1 | Coat form | Белая,густая, однородная масса, при высыхании образует матовое покрытие |

| 2 | Non-volatile matter content, min | 50 |

| 3 | Drying time to the 3rd degree at 20±2°С, max | 1 |

| 4 | Brookfield dynamic viscosity, MPa.sec, min | 17000 |

| 5 | Fineness, mkm, max | 50 |

| 6 | Peeling characteristics | Does not peel off metal items |

Fire retarding coat application

RECOMMENDED PRIMERS: ГФ-021 or Epiprime-046

METHODS: brush, palette-knife, Graco airless-spraying guns

The following conditions shall be ensured when applying the coat::

- air temperature - +5 ÷ +35º С;

- relative air humidity - 80% max;

- difference between air temperature and dew point - 3º С min;

- atmospheric precipitation - should not be any;

- air condition - as per GOST 17.2.3.02.

INTERLAYER DRYING: 5 to 6 hours to the 3rd degree at 20° С

Application of the Bronya Fire Protection compound together with Bronya liquid ceramic thermal insulating coats.

Fire retarding and thermal insulating coat based on Bronya Fire Protection compound is a system consisting of Bronya primer, Bronya liquid ceramic thermal insulating coat, fire retarding coat Bronya Fire Protection and additional (protective) layer of Bronya hydrophobisator.

Bronya Fire Protection has the following advantages:

- Higher fire resistance rating (R) of the coated structures - from R45 to R120. Thickness is selected according to Table 1 and 2.

- When used together with LCTIM, the coat does not impair its thermo-physical properties (including those of competing brands) and allows the system to get the non-flammable rating.

- Unlike its equivalents, Bronya Fire Protection should be colored, but this does not impair fire resistance of the surface;

- It has the same base as the LCTIM Bronya, what, when jointly used, allows to get a perfect non flammable system Bronya NF with high indicators of fire resistance, physical and thermo-physical properties.

- Possibility to use it for fire protection and thermal insulation of metal structures (with the use of LCTIM Bronya Classic and Bronya Antirust) as well as enclosing structures (with the use of Bronya Facade and Bronya Winter).

- The coat (without additional protection layer) is designed for application inside buildings during 30 years.

- Coating group according to GOST 9.032 - special (5/3).

- Color of the fire retarding coat is white, tone is not normalized, the compound is colored by not more than 1%.

- Color of an additional (protective, decorative) layer is not normalized.

- Fire-proof efficiency group according to GOST P 53295 is 2;

- Fire resistance rating ensured by the coat according to GOST 30247 is R15...R120.

- Fire retarding properties of the coat comply with GOST P 53295 "Fire retardant for steel structures. General requirements. Method for fire resistance efficiency determination", GOST 30247.1 "Structural units. Fire resistance test procedure. Bearing and enclosing structures".

Dependence of dry layer thickness of the Bronya Fire Protection coat on the required fire resistance rating and mass factor.

Table 1 - Table presentation of dependence of Bronya Fire Protection coat thickness on the required fire resistance rating (R) and mass factor (MF).

|

Mass factor, mm |

Fire resistance rating, min | |||||||

|

45 |

60 |

90 |

120 |

|||||

| thickness, mm | consumption, kg/m² | consumption, kg/m² | consumption, kg/m² | consumption, kg/m² | consumption, kg/m² | thickness, mm | consumption, kg/m² | |

|

2,4 |

1,2 |

1,69 |

1,53 |

2,15 |

- |

- |

- |

- |

|

2,6 |

1,21 |

1,8 |

1,56 |

2,29 |

- |

- |

- |

- |

|

2,8 |

1,18 |

1,74 |

1,51 |

2,22 |

- |

- |

- |

- |

|

3 |

1,14 |

1,69 |

1,47 |

2,16 |

- |

- |

- |

- |

|

3,2 |

1,11 |

1,64 |

1,42 |

2,09 |

- |

- |

- |

- |

|

3,4 |

1,07 |

1,59 |

1,38 |

2,03 |

2 |

2,82 |

- |

- |

|

3,6 |

1,04 |

1,53 |

1,34 |

1,96 |

2,26 |

3,33 |

- |

- |

|

3,8 |

1 |

1,48 |

1,29 |

1,9 |

2,21 |

3,27 |

- |

- |

|

4 |

0,97 |

1,43 |

1,25 |

1,83 |

2,17 |

3,2 |

- |

- |

|

4,2 |

0,93 |

1,37 |

1,2 |

1,77 |

2,12 |

3,14 |

- |

- |

|

4,4 |

0,9 |

1,32 |

1,16 |

1,7 |

2,08 |

3,07 |

- |

- |

|

4,6 |

0,86 |

1,27 |

1,11 |

1,64 |

2,03 |

3,01 |

- |

- |

|

4,8 |

0,83 |

1,21 |

1,07 |

1,57 |

1,99 |

2,94 |

- |

- |

|

5 |

0,79 |

1,16 |

1,03 |

1,51 |

1,94 |

2,87 |

- |

- |

|

5,2 |

0,76 |

1,11 |

0,98 |

1,44 |

1,9 |

2,81 |

- |

- |

|

5,4 |

0,72 |

1,06 |

0,94 |

1,38 |

1,85 |

2,74 |

- |

- |

|

5,6 |

0,69 |

1 |

0,89 |

1,31 |

1,81 |

2,68 |

- |

- |

| 5,8 |

0,62 |

0,87 |

0,8 |

1,14 |

1,76 |

2,61 |

- |

- |

| 6 |

0,65 |

0,95 |

0,85 |

1,25 |

1,72 |

2,54 |

- |

- |

| 6,2 | 0,65 | 0,95 | 0,85 | 1,25 | 1,67 |

2,48 |

- |

- |

| 6,4 | 0,65 | 0,95 | 0,85 | 1,25 | 1,63 |

2,41 |

- |

- |

| 6,6 | 0,65 | 0,95 | 0,85 | 1,25 |

1,58 |

2,35 |

- |

- |

| 6,8 | 0,65 | 0,95 | 0,85 | 1,25 |

1,54 |

2,28 |

- |

- |

| 7 | 0,65 | 0,95 | 0,85 | 1,25 |

1,49 |

2,22 |

- |

- |

| 7,2 and more | 0,65 | 0,95 | 0,85 | 1,25 |

1,3 |

1,83 |

2,3 |

3,2 |

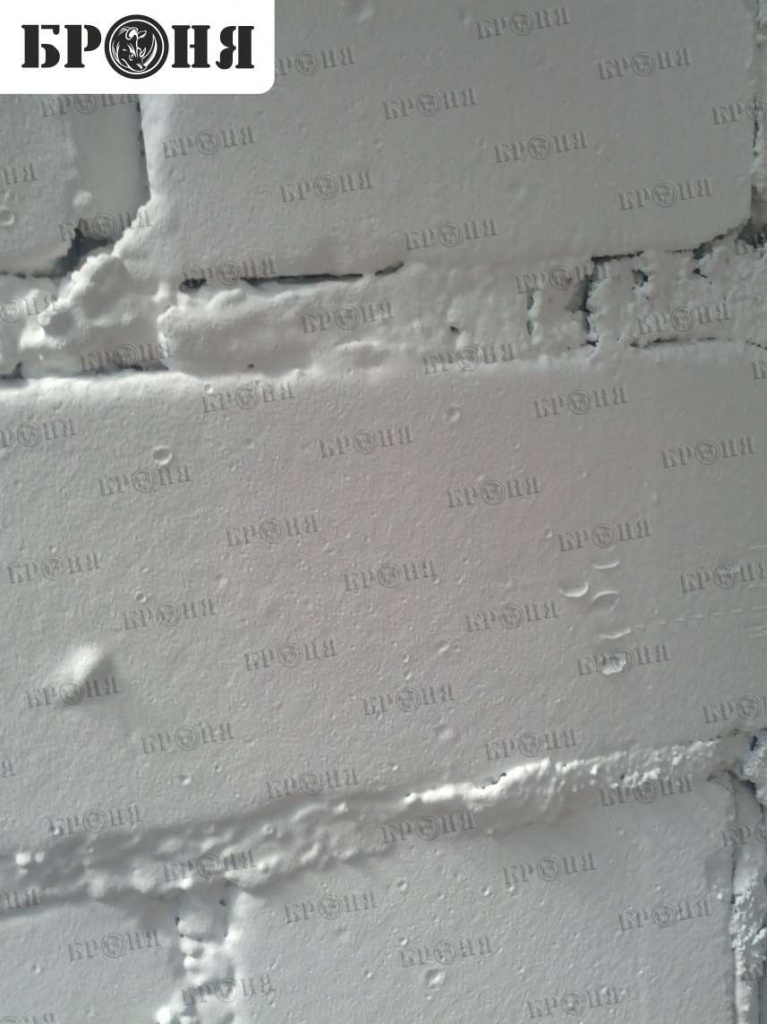

Bronya Fire Protection. Application by brush

Bronya Fire Protection. Application by brush Bronya Fire Protection. Application by Graco.

Bronya Fire Protection. Application by Graco.