Liquid thermal insulation BRONYA ANTIRUST

Liquid thermal insulation Bronya Antirust This is the first and unique material developed in Russia which can be applied directly onto the rusted surface. It is enough to just remove loose rust with a wire brush and right after that thermal insulation Bronya Anrirust can be applied following its application guide. Extra-fine thermal insulation Bronya Antirust is a special compound with improved adhesion and rust-preventing characteristics. It is resistant to UV light and chemicals (salt solutions, acids, alkali, some types of oil products). The coat increases the service life of isolated surfaces and protects against corrosion.

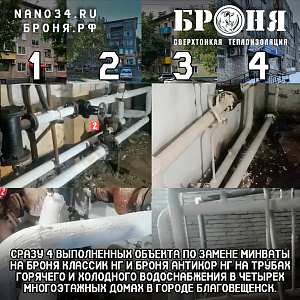

Extra-fine liquid insulation Bronya Antirust is used for thermal insulation of construction steel structures, metalware, pipelines, various industrial equipment exposed to high humidity or hostile environment. Operating temperature is from -60°С to +150°С.

When Bronya Antirust is used for thermal insulation of in-service structures and pipelines, it significantly decreases labor costs as it does not require special preparation of the working surface.

For cost reasons, Bronya Antirust can be applied as a first layer and classic thermal insulation Bronya for further layers.

Application of Bronya Antirust helps to:

- decrease or completely eliminate condensed water formation on cold water pipelines and air ducts;

- isolate equipment without process shutdown;

- cut repair costs in case of emergencies by reducing time spent for leak search and old isolation removal;

- prevent metal surfaces from thermal distortion;

- this coat is a base for application of other modifications.

For instance, rated thickness of the extra-fine thermal insulation applied onto a ferrous metal tank is 2.5mm. At least 6 layers (1 layer of primer and 5 layers of 0.5mm coat with interlayer drying of 24 hours) need to be applied if using competitors' materials (mainly US and Canada) as well as our basic modification Bronya Classic. Our solution requires only three layers:

1st layer - 0.5mm of Bronya Antirust (this is not only corrosion lock but also modifier, adhesion promoting agent and hydroisolator (due to a high rate of film formation).

2nd layer after 24 hours - 1mm of Bronya Facade

3rd layer after 24 hours - 1mm of Bronya Facade

Order a free sample and you will see that claimed specifications are true! You can fine Bronya Classic guideline in Technical Documentation section.

Extra-fine thermal insulation Bronya Antirust is delivered in the following packages:

| Bronya Antirust 5L | Bronya Antirust 10L | Bronya Antirust 20L |

|

|

|

Table of Bronya Antirust specifications

| Factor | Unit | Value |

|---|---|---|

| Coat form | Smooth, uniform, mat gray (beige) color film | |

| Coat resistance to temperature drop from -40°С to +60°С |

Coat form |

no changes |

| Service life for concrete and metal surfaces in boreal climate (Moscow) | years | not less than 15 |

|

Material thermal conductivity factor |

W/m°С | 0,0012 |

|

Material vapor conductivity factor |

mg/m h Pa | 0,003 |

| Surface temperature during material application | °С | от +7 до +150 |

|

Service temperature |

°С |

от -60 до +150 |

| Material density at 20°С, kg/m3 | kg/m3 | 600±10% |

| Volatile matter content, max | % | 43 |

| Hydrogen ion exponent | рН | 7,5-11,0 |

| Drying time and film formation at 20±2°С, min | h | 24 |

|

Coat adhesion with respect to the peeling-off force, min — to concrete and brick surface — to steel |

MPa |

1,3 2,2 |

|

Coat resistance to static impact at 20±2° С, min — Water — 5% NaOH solution |

Coat form |

no changes no changes |