About us

INTRODUCTION

Our company GC VIRTS was founded in 2008.

Today, Bronya is the flagship of the market, and we are the leader in the number of developments, production, certification, testing; and the introduction of new modifications of ultrathin heat insulators, and by implementing them all over the globe, giving them the status of standard and traditional, we are the legislator of criteria in our segment. The products created by us have made changes to the standards required for this type of materials, the quality and performance of which are confirmed by both a rich portfolio of completed objects and a package of documents, including: confirmations of accredited laboratories and institutes, the most famous admissions and certificates. Only in Russia we are represented by about 400 dealerships.

We have extensive experience working with large, state-owned companies: Alrosa, Rosneft, Gazpromneft, Mosenergo, Russian Railways, Lukoil, Tamanneftegaz, Quadra, Unipro, where our products are embedded in projects and used after tender procedures.

The products took part in major repairs in the Crimea, Volgograd, the Republic of Tatarstan, KhMAO, YaNAO, in the cities of the Southern Federal District and the Central Federal District.

OUR DISTRIBUTORS

For 2019, the dealer network of GC VIRC LLC NPO Bronya has more than 270 distribution centers in Russia and in the countries of the Single Customs Union (RF, RB, RK) in all major cities at least 1 distribution center.

There are representatives in all CIS countries, the Baltic States, and almost all EU countries. Also, liquid thermal insulation Bronya is represented by distribution centers in Belarus, Ukraine, Kazakhstan, Belgium, Hungary, Serbia, Czech Republic, Bulgaria, Poland, Romania, Lithuania, Estonia, Latvia and other countries. In the Arab world - Morocco, UAE, Saudi Arabia, Bahrain. In Asia - Indonesia, South Korea, China, Mongolia, Vietnam, New Zealand. Latin America - Argentina, Chile, Ecuador.

Over the years, our company has accumulated invaluable experience, which we are always happy to share with you. We regularly conduct training on the theory and practice of work in the field of implementation and application of Bronya coatings, provide all necessary technical, advertising and information support and materials. More information by link

CERTIFICATION

Very important! All thermal insulation coatings " Bronya" are included in the Classifier of construction resources of the Federal State Information System of Pricing in Construction The Ministry of Construction of the Russian Federation. NPO Bronya is the only manufacturer of liquid heat insulators in the world with a number of advantages:

- thermal conductivity 0.001 W/m°C and other thermophysical and physical characteristics are confirmed by dozens of laboratory conclusions of reputable accredited laboratories (including tests according to GOST 7076-99, ASTM);

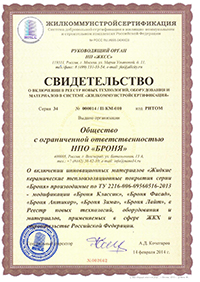

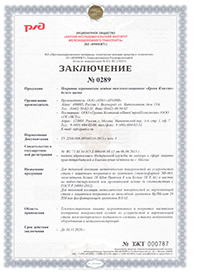

- availability of the highest tolerances, certificates, permits and certificates: Technical certificate of the Ministry of Construction of the Russian Federation, the Customs Union of the Republic of Belarus, CE certificates, Russian Railways (VNIIZhT), Maritime Register, River Register, Mosstroysertification, Gazpromsertification, Teksert, Gazpromenergoexpert and others. You can get acquainted with the full list by passing by link

- The material "Bronya" has the code of the All-Russian product classifier (OKP) 221600 - this is "coatings".

- The "Bronya" material is available in modifications having the G1 or NF flammability groups. This is evidenced by the fire certificates and protocols to them , NF modifications have identical declared and confirmed thermophysical indicators with G1

- Today we have 8 Registered inventions, Patents both for liquid thermal insulation and for its types of applications.

Thanks to the above-mentioned documents, confirmations and approvals, projects with thermal insulation coatings "Bronya" successfully pass state expertise. We add that the products of "Bronya" and most of its applications are officially patented.

We present to your attention a compilation of the registered inventions of Bronya (presentation - 8 Bronya patents) with a description of the fields of activity and tasks to be solved

OUR PRODUCTION

The production in our company is equipped with exclusively modern high-tech equipment from leading world manufacturers. such as the dissolvers NETZSCH (Germany), SIEMENS (Germany), HORIBA (Japan), Beneq Oy (Finland) and OBLF GmbH (Germany), which ensures high quality and reliability of all production processes. We use only high-quality imported raw materials of chemical industry leaders, such as BASF Concern (Germany), AZKO NOBEL (Netherlands), 3M (USA), for the manufacture of ultra-thin ceramic thermal insulation of the Bronya series. It is worth noting that the quality control system for the manufacture of ultrathin thermal insulation Bronya plays an important role in all this. The production process consists of several levels of control. At the initial stage of which we analyze the quality of the raw materials. During the current (interoperative) control, standards are set, the results achieved are compared with the established standards and the necessary corrective actions are taken. And the final stage is quality control of manufactured products for compliance. The combination of high-precision equipment, high-quality raw materials, control systems and the experience of our employees, which is based on regular attendance of thematic seminars and training courses, allows us to achieve excellent results in a complex multi-stage manufacturing process of ultra-thin thermal insulation of the Bronya series.

We are conducting research work on the creation of new modifications of the series of ultrathin liquid thermal insulation Bronya and modernization of formulations and technologies.

ITO TRAINING CENTER

We provide support and advice to our partners at all stages and in all tasks that arise during the promotion and implementation of Bronya in order to use as little labor and financial resources as possible and at the same time achieve maximum results. For your presentations to clients of a certain cluster, we have specific cases, for any level of technical competence, we have operational and professional consultations both in the form of quick solutions and collections and super-complex and voluminous thermal calculations in graphs. For trade marketing , there is a very rich and constantly updated brandbook , scripts for exhibitions and seminars .All over the world , the company Bronya helps companies and people to achieve success in saving heat and resources on a daily basis . We contribute to the development of the world through environmental protection, corporate and personal responsibility and economic progress. We use our scientific developments and innovations to make a real difference in the lives of people around the world.

Our company was founded in 2008. We have extensive experience in the development, production and implementation of innovative building materials, giving them the status of standard and traditional. Today, our main focus is the production of liquid ceramic thermal insulation coatings of the " Bronya " series. At the moment, we are represented in Russia by more than 400 dealerships. The quality and reliability of Bronya coatings were appreciated by consumers of all regions of our country from Kaliningrad to Sakhalin and from Sochi to Murmansk. Also, liquid thermal insulation Bronya is represented by distribution centers in Belgium, Hungary, Serbia, the Czech Republic, Bulgaria, Poland, Romania, Belarus, Ukraine, Kazakhstan, Lithuania, Estonia, Latvia, Latin America, South Korea, Vietnam and other countries. Over the years, our company has accumulated invaluable experience, which we are always happy to share with you. We regularly conduct training on the theory and practice of work in the field of implementation and application of Bronya coatings, provide all necessary technical, advertising and information support and materials.

The production in our company is equipped with exclusively modern high-tech equipment from leading world manufacturers such as NETZSCH (Germany), SIEMENS (Germany), HORIBA (Japan), Beneq Oy (Finland) and OBLF GmbH (Germany), which ensures high quality and reliability of all production processes. We use only high-quality imported raw materials of chemical industry leaders, such as BASF Concern (Germany), AZKO NOBEL (Netherlands), 3M (USA), for the manufacture of ultra-thin ceramic thermal insulation of the Bronya series. It is worth noting that the quality control system for the manufacture of ultrathin thermal insulation Bronya plays an important role in all this. The production process consists of several levels of control. At the initial stage of which our employees analyze the quality of the raw materials. During the current (interoperative) control, standards are set, the results achieved are compared with the established standards and the necessary corrective actions are taken. And the final stage is quality control of manufactured products for compliance. The combination of high-precision equipment, high-quality raw materials, control systems and the experience of our employees, which is based on regular attendance of thematic seminars and training courses, allows us to achieve excellent results in a complex multi-stage manufacturing process of ultra-thin thermal insulation of the Bronya series.

The quality management system of the ultrafine thermal insulation Bronya and its production is certified in the ISO 9001-2008 system for compliance with the requirements of the international standard and can be used in Russia without restriction. In addition, experts from such organizations as the Russian Maritime Register of Shipping, the River Register of Shipping, Gazprom, etc. visited and evaluated our production. Liquid ceramic thermal insulation Bronya has passed laboratory tests of all physical and thermophysical parameters by certified laboratories. You can view the results of the conclusions and tests on our website in the section Acts, reviews and conclusions.

Our company conducts research work on the creation of new modifications of the series ultrafine liquid thermal insulation Bronya and modernization of formulations and technologies, as well as a detailed analysis of the quality of materials together with specialists from the Department of Chemistry and Technology of Processing Elastomers of Volgograd State Technical University and the Department of Architecture of Volgograd State University of Architecture and Civil Engineering. Scientific supervisors are doctors and candidates of technical sciences, professors.