Presentation

ULTRA-THIN THERMAL INSULATION BRONYA

We recommend you the printable versions of the presentations:

Download the Presentation Bronya (print version)

|

|

|

| general presentation- (25 pages) | recommendations for use- (50 pages) | scope of application- (8 pages) |

Volgograd Innovation Resource Center offers you the development of Russian scientists - liquid ceramic thermal insulation material Bronya, superior in its thermophysical properties to known analogues. Own production, high-quality imported raw materials of the leaders of the chemical industry and the leading sales volume, allows us to offer our customers an unprecedented price for Russia and an exclusive line of modifications of ultrathin thermal insulators Bronya. And this is with the most stable and corresponding to the declared characteristics indicators. Also, it would not be superfluous to note that by the efforts of our technical specialists, such analogues as ultrathin thermal insulation Bronya and liquid heat insulator alfatek were developed and put into mass production.

Our material has a full package of necessary certificates and fully complies with the declared technical parameters. Bronya Certificates

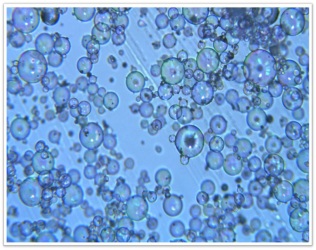

The Bronya ultrathin liquid heat insulator consists of a high-quality acrylic binder, an original developed composition of catalysts and fixators, ceramic ultrathin microspheres with discharged air. In addition to the basic composition, special additives are introduced into the material, which exclude the appearance of corrosion on the metal surface and the formation of fungus in conditions of high humidity on concrete surfaces. This combination makes the material light, flexible, stretchable, with excellent adhesion to the surfaces to be coated. The material is similar in consistency to ordinary paint, it is a white suspension that can be applied to any surface. After drying, an elastic polymer coating is formed, which has unique thermal insulation properties compared to traditional insulators and provides anti-corrosion protection. The uniqueness of the insulating properties of the material is the result of intense molecular exposure to rarefied air located in hollow spheres.

|

|

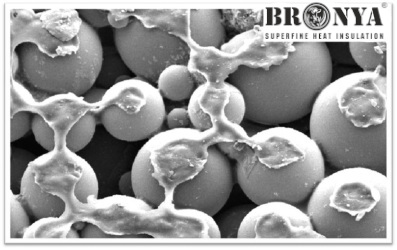

| Microsphere under a microscope | Thermal insulation Bronya under a microscope |

|

|

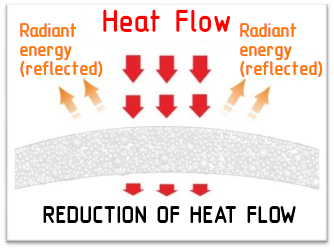

| Shooting an electric stove with a thermal imager, with a half covered with thermal insulation Bronya | Heat flow diagram |

Thermal insulation Bronya. Experiment with ice.

Liquid ceramic thermal insulator Bronya is highly effective in thermal insulation of facades of buildings, roofs, internal walls, window slopes, concrete floors, hot and cold water pipelines, steam pipelines, air ducts for air conditioning systems, cooling systems, various tanks, tanks, trailers, refrigerators, etc. It is used to exclude condensate on cold water pipes and reduce heat loss according to the SNIP in heating systems. The Bronya heat insulator is operated at temperatures from -60 °C to +260 °C. The service life of the material is from 15 years. To date, our material is used at facilities and enterprises of various fields of activity.

How does the material work from the point of view of thermophysics?

Let's start with the fact that there are three ways of heat transfer:

- Thermal conductivity is the transfer of heat in a solid due to the kinetic energy of molecules and atoms from a more heated to a less heated part of the body.

- Convection is the transfer of heat in liquids, gases, and bulk media by the flows of the substance itself.

- Radiant heat transfer (thermal radiation) — electromagnetic radiation emitted by a substance and arising due to its internal energy.

Thermodynamics is a science that studies the laws of mutual transformation and energy transfer. The result of these processes is a temperature equilibrium in the entire system.

The method and efficiency by which the insulating material blocks the redistribution of heat, i.e. the process of temperature equilibrium, and determines the quality of insulation.

Heat transfer is a convective or radiant heat exchange between the surface of a solid and the environment. The intensity of this heat exchange is characterized by a heat transfer coefficient.Liquid ceramic thermal insulation material Bronya is a complex, multi-level structure in which all three methods of heat transfer are minimized.

Ceramic thermal insulator Bronya consists of 80% microspheres, respectively, only 20% of the binder can conduct heat due to its thermal conductivity. The other part of the heat is accounted for by convection and radiation, and since the microsphere contains discharged air (the best insulator, after vacuum), the heat loss is not great. Moreover, due to its structure, the material has a low heat transfer from the surface, which plays a crucial role in its thermophysics.

Thus, it is necessary to separate two terms: Insulation and Heat insulator, because in these materials the physics of the heat transfer process is different:

insulation - the principle of operation is based on the thermal conductivity of the material (min. plate)

the heat insulator is based more on the physics of waves.

The thickness of the thermal insulation layer of the ultrathin thermal insulator Bronya varies from 1 to 6 mm, the subsequent increase practically does not affect its effectiveness.

MODIFICATIONS

For today, liquid thermal insulation Bronya has the following industrial modifications —

1. Bronya Classic and Bronya Classic NF

The basic modification is the best liquid thermal insulation you've worked with. It is a film-forming modification that allows you to isolate objects with a surface temperature of up to +200 ° C on a permanent basis. It has two forms of release: Low-flammable (G1) and Non-flammable (NG)

2. Bronya Standard and Bronya Standard NF

Liquid thermal insulation Bronya Standard - budget version of the modification Bronya Classic - has the same thermophysical characteristics (absolutely identical in quantity-volume of microspheres produced by "3M"), but has a limitation of the peak maximum operating temperature of +140 ° C.

3. UNIVERSAL Bronya and UNIVERSAL Bronya NF

Liquid thermal insulation Universal Bronya is a budget ultrathin thermal insulation that has similar characteristics to Classic Bronya and Standard Bronya. The result of successful, partial implementation of import-substituting technologies in production.4. Antikor Bronya

For the first time in Russia, a unique material has been developed that can be applied directly to a rusty surface. It is enough to simply remove the "raw" (loose) rust with a metal brush, after which you can apply Antikor Bronya insulation, following the instructions.

5. Bronya Metal

Liquid thermal insulation Bronya Metal is a budget ultrathin thermal insulation that has similar characteristics to Antikor Bronya.The result of successful, partial implementation of import-substituting technologies in production. Ultrathin thermal insulation modification Bronya Metal is a highly effective thermal insulation coating, with additional anti-corrosion properties, and not only a preservative and corrosion modifier.

6. Bronya Facade and Bronya Facade NF

An ultra-thin heat insulator that can be applied in layers up to 1 mm thick at a time, and has increased vapor permeability. A unique material that has no analogues in the world. The first liquid thermal insulation material that can be applied to the facades of buildings.

7. Bronya WALL and Bronya WALL NF

The result of successful, partial implementation of import-substituting technologies in production. An ultra-thin heat insulator that can be applied in layers up to 1 mm thick at a time, with increased vapor permeability.

8. Bronya Light and Bronya Light NF, Bronya Light Nord and Bronya Light Nord NF

Thermal insulation coating Bronya Light is an innovative material for construction and finishing works, designed for the final leveling of internal and external surfaces made of concrete, brick, cement-lime plasters, gypsum blocks and slabs, gas and foam concrete, GCL, GVL, etc. with an operating temperature from -60 to +150 ° C.

9. Bronya Winter and Winter NFFor the first time in Russia, a material has been developed with which it is possible to work up to -35 ° C. Thermal insulation Bronya Winter is the latest development in the line of ultrathin liquid ceramic thermal insulation materials. Unlike all other GIT materials presented on the Russian market, work on applying the modification of Bronya Winter can be carried out at negative temperatures, up to -35 ° C., whereas the minimum application temperature of conventional GIT cannot be lower than +5 ° C. Bronya Winter consists of a composition of special acrylic polymers and microgranules of foam glass dispersed in it, as well as pigmenting, flame retardant, rheological and inhibitory additives.

Now you are not afraid of the "winter recession" in construction!

10. Bronya NORD and Bronya NORD NF

Liquid thermal insulation Bronya Nord is a budget ultrathin thermal insulation that has similar characteristics to Bronya Winter. The result of successful, partial implementation of import-substituting technologies in production. Unlike all other GIT materials presented on the Russian market, work on the application of the Bronya Nord modification can be carried out at negative temperatures, up to -35 ° C, while the minimum application temperature of similar GIT cannot be lower than -20 ° C.11. Bronya Fire Protection

One-component composition Fire protection BRONYA is designed to increase the fire resistance limit of steel structures and structures for industrial and civil purposes, from 45 min to 120 min.Increases the fire protection class (R) of the covered structure, from R45, R90 and R120 (certified)

- Does not worsen the thermophysical properties of the gastrointestinal tract (including competing brands), gives a group of combustibility NF (non-combustible).

- Having a common basis with the GITM Bronya, when used together, it ideally creates a heat-insulating non-combustible coating system BRONYA Fire protection, with excellent physical and thermophysical properties.

Anti-condensate coating Bronya ANTI-CONDENSATE PRO

It is applied directly to the condensing surface with a thick technological layer!

ANTI-CONDENSATE BRONYA is a modification of the gastrointestinal tract designed for use in industry, reconstruction and repair of equipment. A unique material applied directly to wet and wet surfaces of pipelines and equipment of various shapes and configurations in operation when it is impossible to stop the technological process, or the supply of liquids through pipelines.

An innovative solution to the problem of condensation on metal, glass, plastic, etc. surfaces of pipes and equipment. Prevents the accumulation and formation of moisture, which, coming off the surfaces covered with condensate, negatively affects the safety of equipment and items located in industrial, administrative, office premises. After the use of BRONYA ANTI-CONDENSATE, this problem is completely eliminated, which prolongs the service life of pipes and equipment.

Modifications are being prepared for commercial release (laboratory samples are already available— -

Modification of the Volcano. Ultra-thin thermal insulation material with an operating temperature range up to + 540 C.

Our products, created on the basis of the experience of creating domestic analogues, have already proven themselves in the market of professional thermal insulation, have the following advantages:

• Can be applied to metal, plastic, concrete, brick and other building materials, as well as to equipment, pipelines and air ducts.

• Have perfect adhesion to metal, plastic, propylene, which allows you to isolate the coated surface from the access of water and air.

* Are not permeable to water and are not affected by an aqueous salt solution. The coatings protect the surface from moisture, precipitation and temperature changes.

• Effectively reduce heat loss and increase corrosion protection.

• Protects the surface from condensation.

* A coating layer with a thickness of 1 mm provides the same insulating properties as 50 mm of rolled insulation or brickwork with a thickness of 1-1.5 bricks.

* Are applied to the surface of any shape.

* Do not create additional load on load-bearing structures.

• Prevents temperature deformations of metal structures.

• Reflect up to 85% of radiant energy.

• Provide constant access to the inspection of the insulated surface without the need to stop production, downtime associated with repairs, and failures in the operation of production equipment.

• Are not destroyed by UV radiation.

* Fast coating procedure reduces labor costs compared to traditional insulators (easily and quickly applied with a brush, airless application apparatus).

* Easily repaired and restored.

• Are an insulating material that does not support gorenje. At a temperature of 260 ° C they are charred, at 800 ° C they decompose with the release of carbon monoxide and nitrogen oxide, which helps to slow down the spread of the flame.

• Environmentally friendly, non-toxic, do not contain harmful volatile organic compounds.

* Resistant to alkalis.

* Hydrogen index (pH) 8.5 - 9.5

* The time of complete drying of one layer is 24 hours

• Calculated thermal conductivity at 20°C 0.001 W/m °C

* Fully certified in Russia.

Liquid ceramic thermal insulation materials are currently presented on the Russian market, which find their consumers, thanks to a wide range of applications and ease of use with low labor costs. Since the materials offered are mainly produced abroad, they have a high cost, which limits the possibility of their mass use in construction, energy and housing, etc. Whereas domestic analogues often leave much to be desired, and their "quality" and over-high mark-up for "know-how" cause negativity and bias in the end user towards liquid ceramic thermal insulation materials.

Liquid composite thermal insulation material is the first product that was developed in Russia using the original technology, is made from high-quality imported components and has no analogues in terms of price-quality ratio. The production of the Volgograd Innovation Resource Center is fully certified, which guarantees consistently high quality of the product. Pride in our product is formed from positive ratings and thanks from our customers. Our customers appreciate the impeccable declared and guaranteed functionality and turn to us again and again. We are proud of the quality of our products.